Download ACE Press Release 10/2019

Download ACE Press Release 10/2019

Equinox MHE optimizes compact sorter with ACE miniature shock absorbers

Christmas is approaching. And with the number of online shops, the volume of parcels and packages is increasing. In 2018, there were 330 million deliveries in Germany at Christmas, said the Federal Association of Parcel and Express Logistics, and the trend is rising. The task of sorting plants is to cope with such quantities and above all at peak times. To do this, the sorters must move at high speeds without losing parcels. A new, high-end system does just this with the help of ACE miniature shock absorbers.

Not far from the North Sea lies the Dutch municipality Hillegom. At first glance, it is hard to imagine that one of Europe's most powerful manufacturers of sorting systems is based in the picturesque polder environment. The turnkey products of the company Equinox MHE are characterized among other things by high integration ability. The company offers a wide range of high-quality systems for logistics automation, including manual sorting systems, picking systems and warehouse management systems. Sorting parameters can be individually selected, and in addition to classic indicators such as postal code or shipping route, this includes, for example, the option of sorting by order. A factor that is important for e-commerce companies. Equinox MHE sorters often use trays to transport products in the system. When a product is entered in a tray, it is identified by scanning the barcode. Once the tray has reached the right destination, it will be opened and the product sorted at the right station. From this station products can be directly packed or shipped. The portfolio also includes so-called split tray sorters, which, thanks to their oval shape, are characterized by having stations on both the inside and outside of the oval, which doubles their exits.

Test phase with ACE for best automation solution

For a particularly space-saving design, the Dutch engineers have additionally reduced the curve radii for these models. As a result, the transport containers move so close together in the curves that they can vibrate. In the worst case, this could result in valuable cargo falling from the sorting plant. To avoid this, Equinox MHE contacted ACE, already well-known in its in-house design department for high quality damping solutions. Tjalling Dolman, Equinox MHE’s project manager, about the cooperation: "It is always a positive experience to work with ACE employees on a project. They are always motivated and dedicated partners and, if necessary, like to take a detour if we get better results to achieve the goal of the joint project."

As the speed on the conveyor belt inside the sorting system was much slower on the inside than on the outside, Han Titulaer, who works in the Netherlands and Belgium as a technical consultant for ACE Stoßdämpfer GmbH, first had the idea to use different types of miniature shock absorbers for the inside and the outside of the oval. However, because Equinox MHE preferred to use a single product type for maintenance reasons, seemingly fitting models were first installed and tested on site. This still resulted in vibrations which the damping technology of the built-in models from the SC190 product family was not completely suitable to eliminate permanently. That's why the ACE team returned on site for a readjustment.

Centrifugal forces successfully stopped in tighter curves

There, the right solution was found to be the MC150EUM-PP150 miniature shock absorbers. The secret is a hermetically sealed rolling diaphragm in each absorber. This unique ACE damping technology ensures complete separation of the damping fluid from the surrounding air. It also makes direct installation in a pressure chamber possible to provide end stop damping in pneumatic cylinders up to approximately 7 bar or 100 psi. The rolling diaphragm delivers very low return forces for these maintenance-free, ready-to-install absorbers. Engineers also favor the components due to their integrated positive stop and progressive energy capacities and their wide range of effective weight. Furthermore, the use of a side load adapter allows impact angles of up to 25 degrees.

For Equinox MHE the facts were more decisive that these miniature shock absorbers reliably make the fast movements of the trays and packages in the curves smoother and that they offer the highest service life of up to 25 million cycles on top of their damping performance. Under simple conditions, this already equals four times the life of conventional shock absorbers. Under difficult or vibrating circumstances this number is even higher considering the life expectancy of standard dampers and the MC types provided by ACE. Miniature shock absorbers from this product family are universally applicable as stainless steel options are also available for greater environmental compatibility. In addition to the logistics industry and packaging equipment, they are also used for automation or in material handling equipment, medium robotics and as dampers within machine tools. Thanks to a large number of accessories and connecting parts, installation is fast and uncomplicated. The self-adjusting machine elements installed in the Netherlands have an energy capacity of 20 Nm per cycle which equals 34,000 Nm per hour with a stroke of just 150 mm. Thus, the continuous operation of the sorting system hardly has any limits. Tjalling Dolman's conclusion is also quite positive: "The collaboration was that of partners and therefore very pleasant, the final solution fits perfectly with our requirements. And as we were ready to expect from a supplier known for its quality products, the components work smoothly."

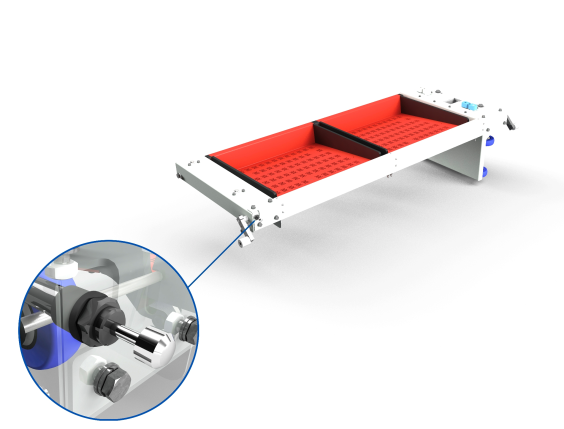

Equinox MHE Split Tray Sorter

Equinox MHE Split Tray Sorter

The calm before the storm: It's not just at Christmas time that thousands of parcels and packages are launched every day from sorting facilities like these

The calm before the storm: It's not just at Christmas time that thousands of parcels and packages are launched every day from sorting facilities like these

For a more compact footprint at logistics facilities, Equinox MHE has reduced the curve radii and uses ACE miniature shock absorbers to maintain high speed also in now tighter corners

For a more compact footprint at logistics facilities, Equinox MHE has reduced the curve radii and uses ACE miniature shock absorbers to maintain high speed also in now tighter corners

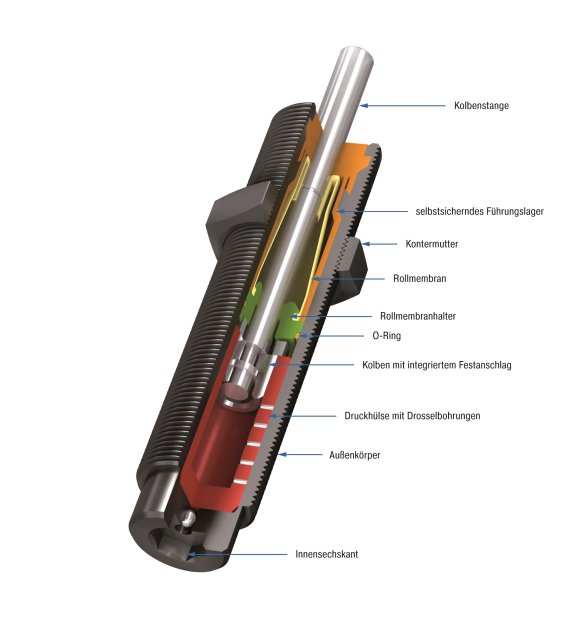

For continuous operation, the self-adjusting, maintenance-free members of the family MC150 to MC650 have proven to be the ideal miniature shock absorbers after tests

For continuous operation, the self-adjusting, maintenance-free members of the family MC150 to MC650 have proven to be the ideal miniature shock absorbers after tests

In addition to reliably braking fast movements in curves, thanks to ACE's unique rolling diaphragm technology, the components are characterized by a maximum service life of up to 25 million cycles

In addition to reliably braking fast movements in curves, thanks to ACE's unique rolling diaphragm technology, the components are characterized by a maximum service life of up to 25 million cycles

Credits

Pictures 1 - 3: Equinox MHE

Pictures 4 and 5: ACE Stoßdämpfer GmbH