Topic: Industrial POWERISE® and Industrial Gas Springs in Tooling Machines at KeyTec Netherlands B.V.

Anyone who produces 1 billion metal pins per year around the clock can report that production is running smoothly. The art lies in making even the steps that are difficult work easily. This is to protect workers while reducing downtime and maintenance periods. KeyTec Netherlands B.V. succeeds in this in an exemplary manner in cooperation with ACE Stoßdämpfer GmbH.

According to the motto "We Industrialize Your Ideas!", KeyTec has been supporting customers from all over the world with high-precision metal parts and plastic components from small to mass-volume quantities since 1999. As a business-to-business supplier, the company implements a wide range of product solutions for the automotive, energy and consumer goods industries as well as for commercial customers at its headquarters in Sittard in the Netherlands. The spectrum ranges from individual parts and multi-technology products to subassemblies and assemblies. This also includes their surface treatment and assembly through metal stamping, bending and deep drawing as well as plastic injection molding and related technologies.

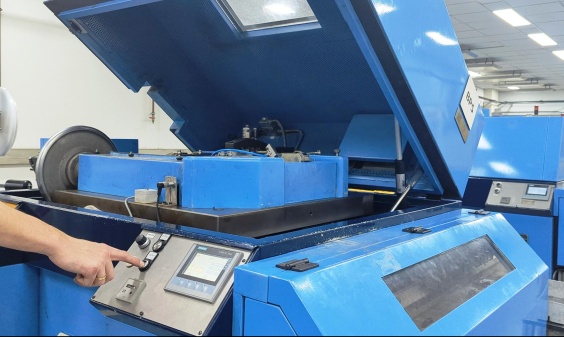

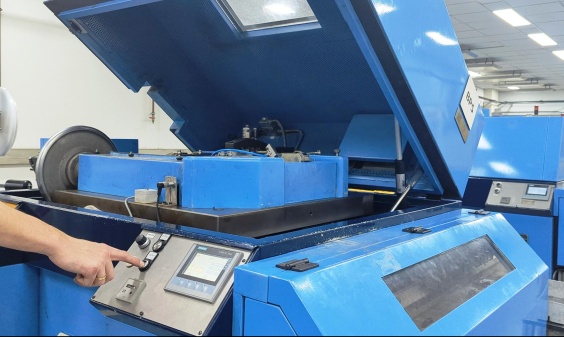

One of KeyTec Netherlands B.V.'s machine rooms in Sittard with butting machines for the production of metal pins for battery production.

Partners from Prototype to Series Production

As a privately owned family business, KeyTec works in a project-oriented manner with fast means of communication and quick response to customer questions. In the production facilities and subsidiaries in the Netherlands, the Czech Republic and China, the focus is on design for manufacturing, short turnaround times and close cooperation with selected European and Asian tool manufacturers and partners for automation equipment. This also includes the technical sales team of ACE Stoßdämpfer GmbH, which has been based in the Netherlands for more than 15 years and is responsible for the Benelux countries. The synergies with manufacturers and partners such as ACE serve all of KeyTec's end customers in terms of time-to-market, total cost of ownership, quality and efficiency.

This pragmatic and solution-oriented approach is used daily by KeyTec's creative and experienced staff in all customer challenges to industrialize products and assemblies. The company is certified according to IATF 16949, ISO 9001 and ISO 14001 and convinces with future-oriented solutions, as the following application proves.

Wanted: More Ease of Use in Metalworking

For various customers from the electronics industry, KeyTec carries out certain work steps for the production of batteries. These are equipped with special pins, of which around one billion pieces are produced per year in three-shift operation in various designs at the headquarters in Sittard. This requires machines that convert wire both swiftly and precisely, at the same time ensuring uniform quality with high productivity. Processing is done from the coil, with straightening, cutting and cold forming taking place in the machine. Every eight hours, once per shift, these machines are supplied with new material by the operating personnel. To do this, the upper hoods of the machine, which weigh around 45 kg, have to be opened. This is also necessary on a regular basis when the tools of the machines have to be cleaned. In the rare event of machine failures, the hoods have to provide fast access to the machines and their levers and clamping jaws and the bushing-tool systems as well as to the cross slides and heads inside.

An important reason for the considerable weight of the hoods is that the closed machine housing is supposed to effectively insulate the work noise for occupational health and safety reasons. In addition, the integrated drives, as well as the electronics and central lubrication, should be easily accessible to the maintenance team from all sides. Among other parts, two industrial gas springs are responsible for this on each hood. Provided by ACE, these ready-to-install, maintenance-free and sealed type GS-28-200-EE-920N components are durable and filled with pressurized nitrogen gas. With an extension force of originally 920 Newton (N) per gas spring, they reliably supported the muscle strength of the operating personnel when opening and closing the hoods. From the point of view of increased ergonomics and to further relieve the burden on employees, KeyTec's technicians asked ACE's sales engineers in the Netherlands about other ways to improve operating comfort and to modernize the existing tooling machines in a smart way.

Found: Industrial POWERISE® in Combination with Existing Gas Springs

Han Titulaer from the Benelux sales team then mentioned ACE's affiliation with Stabilus Group and presented the electromechanical drive systems called Industrial POWERISE®. For many years, similar components provided by Stabilus have been reliably performing their services millions of times as actuators on tailgates as well as on engine and trunk hoods in a wide variety of models of the best-known automobile manufacturers.

Adapted and perfected for industrial use in recent years by the technical teams at ACE and Stabilus, these components are therefore also suitable for the 45 kg hoods on the tooling machines in Sittard – in combination with the gas springs already installed. Using their extension forces, which were reduced to 700 N per unit by reducing nitrogen via ACE’s valve technology, the team identified IPR35-V-24A-200-8-65C actuators as the most suitable components for this specific case to increase operator comfort.

Once mounted and optionally powered via a 12 or 24 volt connection, these Industrial POWERISE® reliably enable stroke movements of 200 mm in length at spindle pitches of 8 mm per revolution at the touch of a button. In this case, lifting and lowering takes place with an additional force of 65 N per actuator in combination with the gas springs. Ralf Küppers from Technical Sales and Robin Hilke, ACE's Product Manager for Industrial POWERISE®, set these exact values on site at KeyTec, whereby the electrical control system could also be precisely adapted to the machine hoods via analogue interfaces.

"Sensitive obstacle detection was important to our partners at KeyTec Netherlands B.V., which we set up together via our software. We assumed an estimated force of 30 N at the leading edge when the hood was closed. This detects obstacles such as fingers or hands, and the movement stops within milliseconds before injury or damage occurs."

Robin Hilke, Product Manager Industrial POWERISE®, ACE Stoßdämpfer GmbH

Industrial POWERISE® now brings power and comfort to industrial applications at the touch of a button, also ideally suited for operation in combination with ACE industrial gas springs.

In general, the new actuators from ACE are available with spindle pitches between 2 and 25 mm and then take over lifting, lowering and positioning optionally with forces between 250 N and 4,000 N. With stroke ranges between 50 mm and 350 mm, designers can thus choose precise as well as powerful and versatile vertical and horizontal motion control. What’s more, this solution can operate as an automatic positioning system for their applications too. Since the noise level of the drive is only 55 dB (A), Industrial POWERISE® also enables quiet operation. These advantages make the integration of ACE's new drives perfect for flaps, hoods and vertical linear adjustments.

In the application described here, it proves to be a further advantage that the combination with ACE gas springs relieves the drive, which means that the weight can be higher, the movement by hand more ergonomic and the travel speed faster. In practice at KeyTec Netherlands B.V. in Sittard, this is synonymous with easier operation, faster access to the machine's interior and greater satisfaction of all parties involved with the quality of work processes and the reduction of noise.

ACE Stoßdämpfer GmbH

Albert-Einstein-Str. 15

40764 Langenfeld

Germany

Tel.: +49 2173-9226-10

info@ace-int.eu

www.ace-ace.de

KeyTec Netherlands B.V.

Rijksweg Noord 281

6136 AC Sittard

The Netherlands

Tel.: +31 46 4113 800

Sebastiaan.laumen@keytec.nl

www.keytecgroup.com/nl/home